Overview

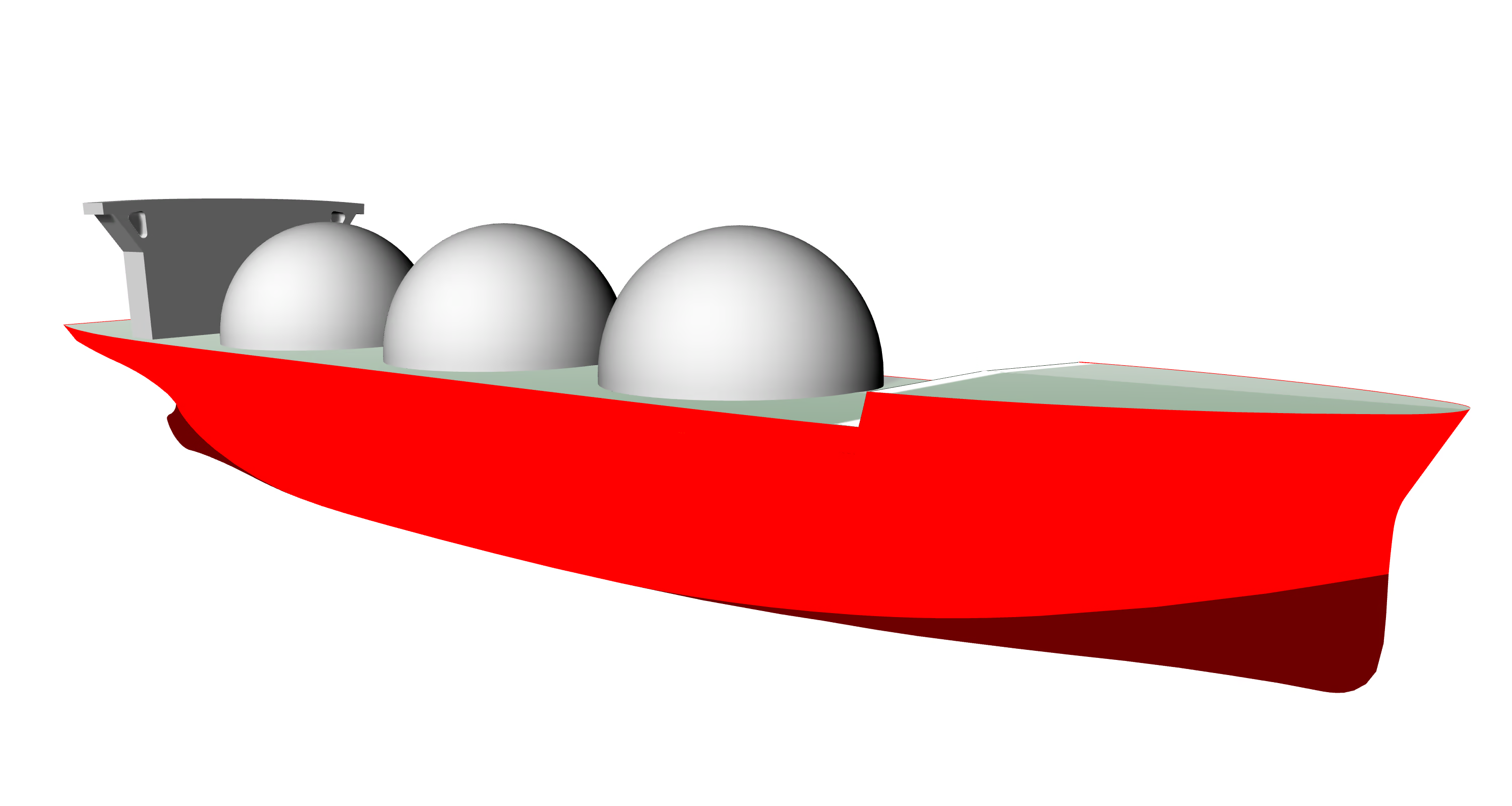

A heavy-duty liquefied natural gas (LNG) carrier designed for high-capacity global transport. Featuring three insulated spherical (Moss-type) tanks, the design prioritizes thermal integrity, structural safety, and operational reliability. This concept demonstrates a practical pathway from CAD model toward a class-compliant, buildable LNG carrier for international energy logistics.

Theoretical Background

Why Spherical Tanks?

- LNG must be transported at -162°C, requiring advanced insulation.

- Spherical (Moss-type) tanks minimize sloshing loads compared to prismatic tanks.

- Structural advantage: self-supporting spheres distribute internal pressure evenly, reducing localized stress.

- Safety: each tank sits partially exposed above deck, allowing easy inspection and limiting fire spread.

Comparison with Other Types

- Moss-type (spherical): Best for safety & robustness.

- Membrane-type (flat prismatic): Higher volumetric efficiency, but more complex insulation.

Our design uses Moss-type to emphasize reliability over capacity density, ideal for a first-step concept.

Design Highlights

- Spherical containment system (Moss-type): Proven global standard for LNG thermal integrity and sloshing resistance.

- Three-tank arrangement: Optimized for load distribution and longitudinal balance of the hull girder.

- Integrated boil-off gas (BOG) management: Concept prepared for reliquefaction or dual-fuel propulsion use.

- Efficient spatial organization: Clear deck layout with accessible piping, reliquefaction, and manifold systems.

Principal Dimensions (Conceptual)

| Parameter | Value | Unit |

|---|---|---|

| Length Overall (LOA) | ~230 | m |

| Beam | ~38 | m |

| Depth | ~22 | m |

| Draft (design) | ~11.5 | m |

| Displacement | ~80,000 | t |

| Cargo Containment | 3 × Moss-type spherical tanks | — |

Values are indicative; to be refined by hydrostatic & structural verification.

Safety & Compliance

- Concept aligned with IGC Code for gas carriers.

- Redundant Emergency Shutdown (ESD) systems.

- Gas detection and inerting systems.

- Segregated ballast and collision zones.

Operational Plan

- Cargo: LNG for long-haul trunk routes.

- Propulsion Options: Dual-fuel (LNG) main engines, or LNG-electric hybrid for emissions compliance.

- Cargo Management: Integrated reliquefaction and BOG recovery for reduced cargo loss.

- Target Route: International LNG supply chain (Asia–Europe, Gulf–Asia).